Raspberries of Cuna de Platero, the stars in Andalucía Directo

January 22, 2016

Cuna de Platero exposes to UHU students its business model and its commitment to R + D + i and digital revolution

March 21, 2018Cuna de Platero modernizes and digitizes all the processes implemented in the Company

– It implements an ambitious project that seeks to continue improving the quality of processes, optimize resources and improve energy efficiency

– The company has invested around eight million euros and executed works for its development during seven months

– It is a commitment to maintain employment with trained professionals and adapted to their new tasks

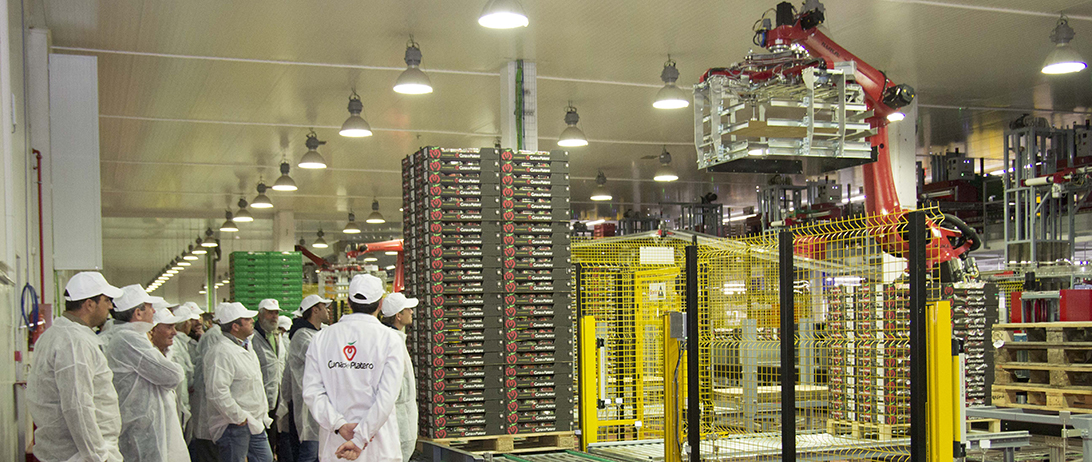

Cuna de Platero carried out the modernization and digitalization of all the processes implemented in the company. This ambitious project, which began to be launched last July, with the completion of the last campaign, seeks to continue improving quality in all processes, optimizing resources and improving energy efficiency. ”This project means for Cuna de Platero the implementation of a new way of working, in which we have made the leap to digitalization”, explained the Chairman, José Manuel Márquez, who adds that “it is a commitment to the maintenance of employment, with professionals trained and adapted to their new job profiles, for which we will rely on our newly created Human Resources department”. This work, which has completely renewed the way of working in Cuna de Platero, means an investment of some eight million euros. “We are aimed to be at the forefront of the sector and provide sustainability to all areas of the company: environmental, social and economic”, Márquez underlined.

With this renovation, Cuna de Platero makes the leap from a traditional work model to a technological and digital one, “always led by professional profiles that accompany this technological investment”.

Some improvements implemented

A new system of packaging and palletizing is one of the novelties that come to Cuna de Platero, optimizing these phases of the value chain, thus improving the control of orders.

On the other hand, the company has digitized all the processes implemented in the Company, with a Business Resource Planning System, also known as Enterprise Resource Planning (ERP) or, integrating the machinery to control all the processes of the value chain, from the reception to the expedition of fruit: production, distribution or human resources.

These innovations “allow us to advance in traceability: planning, measurement and control of all our activity, which will result in improvements in the work environment, a more complete service to our customers and fresh fruit of the highest quality for consumers”.